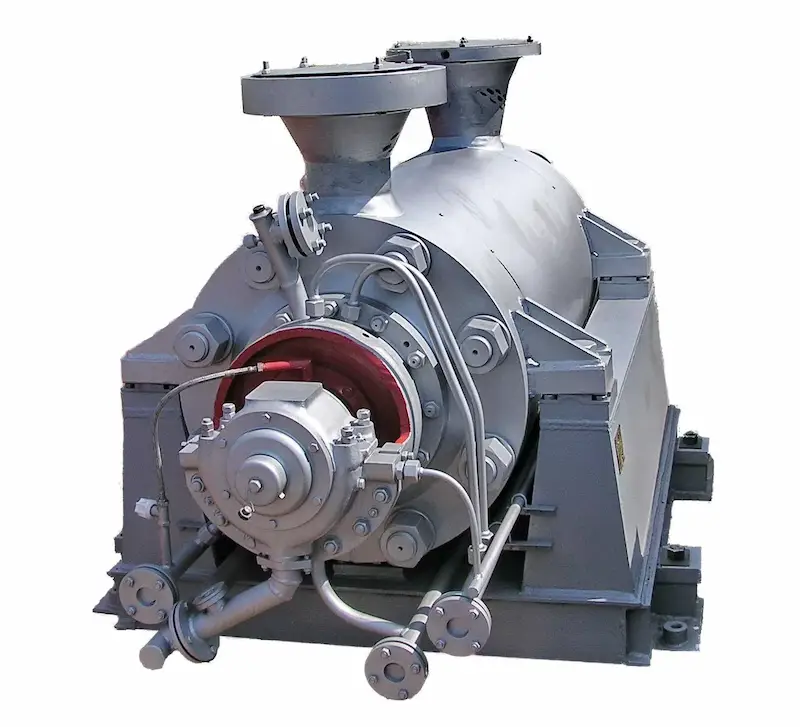

Industrial Boiler Feed Multistage Centrifugal Pump | High Pressure Water Pump for Power Plants & Steam Systems

Product Description

The DG Series Boiler Multi-Stage Centrifugal Pump is designed for high-pressure feedwater and clean water transfer in power plants and industrial systems. With flow from 6.3 to 280 m³/h, head up to 1,000 m, and power range 4.0 to 1,250 kW, it ensures stable operation under demanding conditions. Its horizontal, multistage design offers reliability, high pressure capability, and compatibility with boiler and steam systems.

Keywords: boiler feed pump, multistage centrifugal pump, power plant feedwater pump, high-pressure pump, DG series.

🌍 Applications

- Power Plants & Thermal Stations — delivering boiler feedwater under high pressure

- Industrial Steam Systems — supporting chemical, petrochemical, and refinery plants

- High-Rise Building Water Systems — boosting pressure for upper floors

- District Heating & Hot Water Circulation — in municipal thermal networks

- Desalination & Reverse Osmosis — as high-pressure feed pump

- Clean Water Transfer in Process Systems — in factories needing stable high-pressure water supply

Long-tail / B2B keywords included: “industrial boiler feed pump,” “DG multistage pump for power plant,” “high pressure centrifugal pump supplier.”

⚙️ Technical Data

| Parameter | Specification / Range | Parameter | Specification / Range |

|---|---|---|---|

| Flow Rate | 6.3 – 280 m³/h | Power (Corollary) | 4.0 – 1,250 kW |

| Head Range | 75 – 1,000 m | Inlet Diameter | 40 – 200 mm |

| Medium Temperature | 0 – 170 °C | Operating Pressure | ≤ 40 bars |

| Pump Type | Horizontal Multistage Centrifugal | Installation Orientation | Horizontal inline |

| Standards & Origin | ISO / SUHUA / China |

Note: Efficiency, speed, NPSH data vary by model; detailed curves available upon request.

Product Specifications

| Type | Speed (r/min) | Flow (m³/h) | Flow (L/S) | Head (m) | Efficiency (%) | Shaft power (kW) | Motor Power (kW) | NPSH (m) |

|---|---|---|---|---|---|---|---|---|

| DG 6-25×3 | 2950 | 3.75 | 1.04 | 76.5 | 33 | 2.37 | 5.5 | 2.0 |

| 6.3 | 1.75 | 75 | 45 | 2.86 | 2.0 | |||

| 7.5 | 2.08 | 73.5 | 47 | 3.19 | 2.5 | |||

| DG 6-25×4 | 2950 | 3.75 | 1.04 | 102 | 33 | 3.16 | 7.5 | 2.0 |

| 6.3 | 1.75 | 100 | 45 | 3.81 | 2.0 | |||

| 7.5 | 2.08 | 98 | 47 | 4.26 | 2.5 | |||

| DG 6-25×5 | 2950 | 3.75 | 1.04 | 127.5 | 33 | 3.95 | 7.5 | 2.0 |

| 6.3 | 1.75 | 125 | 45 | 4.77 | 2.0 | |||

| 7.5 | 2.08 | 122.5 | 47 | 5.32 | 2.5 | |||

| DG 6-25×6 | 2950 | 3.75 | 1.04 | 153 | 33 | 4.73 | 11 | 2.0 |

| 6.3 | 1.75 | 150 | 45 | 5.72 | 2.0 | |||

| 7.5 | 2.08 | 147 | 47 | 6.39 | 2.5 | |||

| DG 6-25×7 | 2950 | 3.75 | 1.04 | 178.5 | 33 | 5.52 | 11 | 2.0 |

| 6.3 | 1.75 | 175 | 45 | 6.67 | 2.0 | |||

| 7.5 | 2.08 | 171.5 | 47 | 7.45 | 2.5 | |||

| DG 6-25×8 | 2950 | 3.75 | 1.04 | 204 | 33 | 6.31 | 15 | 2.0 |

| 6.3 | 1.75 | 200 | 45 | 7.63 | 2.0 | |||

| 7.5 | 2.08 | 196 | 47 | 8.58 | 2.5 | |||

| DG 6-25×9 | 2950 | 3.75 | 1.04 | 229.5 | 33 | 7.10 | 15 | 2.0 |

| 6.3 | 1.75 | 225 | 45 | 8.52 | 2.0 | |||

| 7.5 | 2.08 | 220.5 | 47 | 9.58 | 2.5 | |||

| DG 6-25×10 | 2950 | 3.75 | 1.04 | 255 | 33 | 7.89 | 18.5 | 2.0 |

| 6.3 | 1.75 | 250 | 45 | 9.53 | 2.0 | |||

| 7.5 | 2.08 | 245 | 47 | 10.63 | 2.5 | |||

| DG 6-25×11 | 2950 | 3.75 | 1.04 | 280.5 | 33 | 8.68 | 18.5 | 2.0 |

| 6.3 | 1.75 | 275 | 45 | 10.5 | 2.0 | |||

| 7.5 | 2.08 | 269.5 | 47 | 11.71 | 2.5 | |||

| DG 6-25×12 | 2950 | 3.75 | 1.04 | 306 | 33 | 9.47 | 18.5 | 2.0 |

| 6.3 | 1.75 | 300 | 45 | 11.44 | 2.0 | |||

| 7.5 | 2.08 | 294 | 47 | 12.78 | 2.5 | |||

| DG 12-25×3 | 2950 | 7.5 | 2.08 | 84.6 | 44 | 3.93 | 7.5 | 2.0 |

| 12.5 | 3.47 | 75 | 54 | 4.73 | 2.0 | |||

| 15.0 | 4.17 | 69 | 53 | 5.37 | 2.5 | |||

| DG 12-25×4 | 2950 | 7.5 | 2.08 | 112.8 | 44 | 5.24 | 11 | 2.0 |

| 12.5 | 3.47 | 100 | 54 | 6.30 | 2.0 | |||

| 15.0 | 4.17 | 92 | 53 | 7.09 | 2.5 | |||

| DG 12-25×5 | 2950 | 7.5 | 2.08 | 141 | 44 | 6.55 | 11 | 2.0 |

| 12.5 | 3.47 | 125 | 54 | 7.88 | 2.0 | |||

| 15.0 | 4.17 | 115 | 53 | 8.86 | 2.5 | |||

| DG 12-25×6 | 2950 | 7.5 | 2.08 | 169.2 | 44 | 7.85 | 15 | 2.0 |

| 12.5 | 3.47 | 150 | 54 | 9.46 | 2.0 | |||

| 15.0 | 4.17 | 138 | 53 | 10.64 | 2.5 | |||

| DG 12-25×10 | 2950 | 7.5 | 2.08 | 282 | 44 | 13.09 | 22 | 2.0 |

| 12.5 | 3.47 | 250 | 54 | 15.76 | 2.0 | |||

| 15.0 | 4.17 | 230 | 53 | 17.73 | 2.5 | |||

| DG 12-25×11 | 2950 | 7.5 | 2.08 | 310.2 | 44 | 14.4 | 22 | 2.0 |

| 12.5 | 3.47 | 275 | 54 | 17.34 | 2.0 | |||

| 15.0 | 4.17 | 253 | 53 | 19.5 | 2.5 | |||

| DG 25-30×7 | 2950 | 15 | 4.17 | 238 | 50 | 19.44 | 30 | 2.2 |

| 25 | 6.94 | 210 | 62 | 23.1 | 2.2 | |||

| 30 | 8.33 | 192.5 | 63 | 24.90 | 2.6 | |||

| DG 25-30×8 | 2950 | 15 | 4.17 | 272 | 50 | 22.22 | 37 | 2.2 |

| 25 | 6.94 | 240 | 62 | 26.4 | 2.2 | |||

| 30 | 8.33 | 220 | 63 | 28.53 | 2.6 | |||

| DG 85-45×3 | 2950 | 55 | 15.3 | 153 | 63 | 36.38 | 55 | 3.2 |

| 85 | 23.6 | 135 | 72 | 43.3 | 4.2 | |||

| 100 | 27.8 | 117 | 70 | 45.52 | 5.2 | |||

| DG 85-45×4 | 2950 | 55 | 15.3 | 204 | 63 | 48.5 | 75 | 3.2 |

| 85 | 23.6 | 180 | 72 | 57.87 | 4.2 | |||

| 100 | 27.8 | 156 | 70 | 60.7 | 5.2 | |||

| DG 85-45×5 | 2950 | 55 | 15.3 | 255 | 63 | 60.63 | 90 | 3.2 |

| 85 | 23.6 | 225 | 72 | 72.34 | 4.2 | |||

| 100 | 27.8 | 195 | 70 | 75.86 | 5.2 | |||

| DG 85-45×6 | 2950 | 55 | 15.3 | 306 | 63 | 72.75 | 110 | 3.2 |

| 85 | 23.6 | 270 | 72 | 86.81 | 4.2 | |||

| 100 | 27.8 | 234 | 70 | 91.04 | 5.2 | |||

| DG 85-45×7 | 2950 | 55 | 15.3 | 357 | 63 | 84.88 | 132 | 3.2 |

| 85 | 23.6 | 315 | 72 | 101.3 | 4.2 | |||

| 100 | 27.8 | 273 | 70 | 106.2 | 5.2 | |||

| DG 85-45×8 | 2950 | 55 | 15.3 | 408 | 63 | 97.0 | 132 | 3.2 |

| 85 | 23.6 | 360 | 72 | 115.7 | 4.2 | |||

| 100 | 27.8 | 312 | 70 | 121.4 | 5.2 | |||

| DG 85-45×9 | 2950 | 55 | 15.3 | 459 | 63 | 109.1 | 160 | 3.2 |

| 85 | 23.6 | 405 | 72 | 130.2 | 4.2 | |||

| 100 | 27.8 | 351 | 70 | 136.6 | 5.2 | |||

| DG 155-30×2 | 1480 | 100 | 27.8 | 65 | 64 | 27.66 | 55 | 3.2 |

| 155 | 43 | 60 | 75 | 33.77 | 3.9 | |||

| 185 | 51.4 | 55 | 75 | 36.95 | 4.8 | |||

| DG 155-30×3 | 1480 | 100 | 27.8 | 97.5 | 64 | 41.2 | 75 | 3.2 |

| 155 | 43 | 90 | 75 | 50.65 | 3.9 | |||

| 185 | 51.4 | 82.5 | 75 | 55.4 | 4.8 | |||

| DG 155-30×4 | 1480 | 100 | 27.8 | 130 | 64 | 55.32 | 90 | 3.2 |

| 155 | 43 | 120 | 75 | 67.54 | 3.9 | |||

| 185 | 51.4 | 110 | 75 | 73.9 | 4.8 | |||

| DG 155-30×5 | 1480 | 100 | 27.8 | 162.5 | 64 | 69.15 | 110 | 3.2 |

| 155 | 43 | 150 | 75 | 84.42 | 3.9 | |||

| 185 | 51.4 | 137.5 | 75 | 92.37 | 4.8 | |||

| DG 155-30×6 | 1480 | 100 | 27.8 | 195 | 64 | 82.98 | 132 | 3.2 |

| 155 | 43 | 180 | 75 | 101.3 | 3.9 | |||

| 185 | 51.4 | 165 | 75 | 110.8 | 4.8 | |||

| DG 155-30×7 | 1480 | 100 | 27.8 | 227.5 | 64 | 96.81 | 160 | 3.2 |

| 155 | 43 | 210 | 75 | 118.2 | 3.9 | |||

| 185 | 51.4 | 192.5 | 75 | 129.3 | 4.8 | |||

| DG 155-30×8 | 1480 | 100 | 27.8 | 260 | 64 | 110.6 | 180 | 3.2 |

| 155 | 43 | 240 | 75 | 135.1 | 3.9 | |||

| 185 | 51.4 | 220 | 75 | 147.8 | 4.8 | |||

| DG 155-30×9 | 1480 | 100 | 27.8 | 292.5 | 64 | 124.5 | 180 | 3.2 |

| 155 | 43 | 270 | 75 | 152 | 3.9 | |||

| 185 | 51.4 | 247.5 | 75 | 166.3 | 4.8 | |||

| DG 155-30×10 | 1480 | 100 | 27.8 | 325 | 64 | 138.3 | 225 | 3.2 |

| 155 | 43 | 300 | 75 | 168.8 | 3.9 | |||

| 185 | 51.4 | 275 | 75 | 184.7 | 4.8 | |||

| DG 155-67×3 | 2950 | 100 | 27.8 | 228 | 64 | 97.0 | 132 | 3.2 |

| 155 | 43 | 200 | 74 | 114.7 | 5.0 | |||

| 185 | 51.4 | 177 | 72 | 123.9 | 6.6 | |||

| DG 155-67×4 | 2950 | 100 | 27.8 | 304 | 64 | 129.4 | 185 | 3.2 |

| 155 | 43 | 268 | 74 | 152.9 | 5.0 | |||

| 185 | 51.4 | 236 | 72 | 165.1 | 6.6 | |||

| DG 155-67×5 | 2950 | 100 | 27.8 | 380 | 64 | 161.7 | 220 | 3.2 |

| 155 | 43 | 335 | 74 | 191.1 | 5.0 | |||

| 185 | 51.4 | 295 | 72 | 206.4 | 6.6 | |||

| DG 155-67×6 | 2950 | 100 | 27.8 | 456 | 64 | 194 | 275 | 3.2 |

| 155 | 43 | 402 | 74 | 229.3 | 5.0 | |||

| 185 | 51.4 | 354 | 72 | 247.7 | 6.6 | |||

| DG 155-67×7 | 2950 | 100 | 27.8 | 532 | 64 | 226.4 | 350 | 3.2 |

| 155 | 43 | 469 | 74 | 267.5 | 5.0 | |||

| 185 | 51.4 | 413 | 72 | 289 | 6.6 | |||

| DG 155-67×8 | 2950 | 100 | 27.8 | 608 | 64 | 258.7 | 350 | 3.2 |

| 155 | 43 | 536 | 74 | 305.7 | 5.0 | |||

| 185 | 51.4 | 472 | 72 | 330.3 | 6.6 | |||

| DG 155-67×9 | 2950 | 100 | 27.8 | 684 | 64 | 291.1 | 440 | 3.2 |

| 155 | 43 | 603 | 74 | 344 | 5.0 | |||

| 185 | 51.4 | 531 | 72 | 371.9 | 6.6 | |||

| DG 280-43×2 | 1480 | 185 | 51.4 | 94 | 69 | 68.6 | 110 | 3.0 |

| 280 | 77.8 | 86 | 77 | 85.17 | 4.7 | |||

| 335 | 93.1 | 76 | 75 | 92.4 | 6.0 | |||

| DG 280-43×3 | 1480 | 185 | 51.4 | 141 | 69 | 103 | 150 | 3.0 |

| 280 | 77.8 | 129 | 77 | 127.7 | 4.7 | |||

| 335 | 93.1 | 114 | 75 | 138.7 | 6.0 | |||

| DG 280-43×4 | 1480 | 185 | 51.4 | 188 | 69 | 137.3 | 230 | 3.0 |

| 280 | 77.8 | 172 | 77 | 170.3 | 4.7 | |||

| 335 | 93.1 | 152 | 75 | 184.9 | 6.0 | |||

| DG 280-43×5 | 1480 | 185 | 51.4 | 235 | 69 | 171.6 | 300 | 3.0 |

| 280 | 77.8 | 215 | 77 | 212.9 | 4.7 | |||

| 335 | 93.1 | 190 | 75 | 231.1 | 6.0 | |||

| DG 280-43×6 | 1480 | 185 | 51.4 | 282 | 69 | 205.9 | 300 | 3.0 |

| 280 | 77.8 | 258 | 77 | 255.5 | 4.7 | |||

| 335 | 93.1 | 228 | 75 | 277.3 | 6.0 | |||

| DG 280-43×7 | 1480 | 185 | 51.4 | 329 | 69 | 240.2 | 350 | 3.0 |

| 280 | 77.8 | 304 | 77 | 298.1 | 4.7 | |||

| 335 | 93.1 | 266 | 75 | 323.6 | 6.0 |

💡 Features & Benefits

- High Pressure Capability — Able to reach head up to 1,000 m to meet demanding boiler feed requirements.

- Modular Multistage Design — Allows adjusting number of stages to match project head needs, improving flexibility.

- Horizontal Layout — Easier alignment and maintenance in industrial settings.

- Robust Construction for High Load — Designed for continuous duty, strong materials resist wear under high pressure.

- Wide Temperature & Pressure Tolerance — Supports up to 170 °C and 40 bars, compatible with steam-augmented systems.

- Low Vibration & Reliability — Balanced rotors and design minimize vibration, extending life of bearings and seals.

- Serviceability & Spare Parts Access — Inspection and maintenance possible without full disassembly.

- OEM / Export Ready — Direct manufacturer supply, customizable options, and export-standard packaging.

❓ Frequently Asked Questions

Q1: What is the maximum head and flow capacity?

A1: The DG Series pump supports flows from 6.3 to 280 m³/h and heads up to 1,000 m.

Q2: Can this pump be used in power plants as a boiler feed pump?

A2: Yes. It is designed especially for high-pressure boiler feedwater duty in thermal power stations and industrial steam systems.

Q3: What are the operating temperature and pressure limits?

A3: Operates from 0 to 170 °C, and can handle pressures up to 40 bars.

Q4: How do I select the correct model for my project?

A4: Provide your required flow (m³/h), total head (m), operating temperature/pressure, and water quality. We’ll recommend the best stage count and configuration.

Q5: Are there customization options?

A5: Yes. As a pump manufacturer in China, we offer OEM/ODM, custom materials, mechanical seal choices, special coatings, and tailored stages.