Double Suction Split Case Pump | SA Type High-Efficiency Water Pump

Product Description

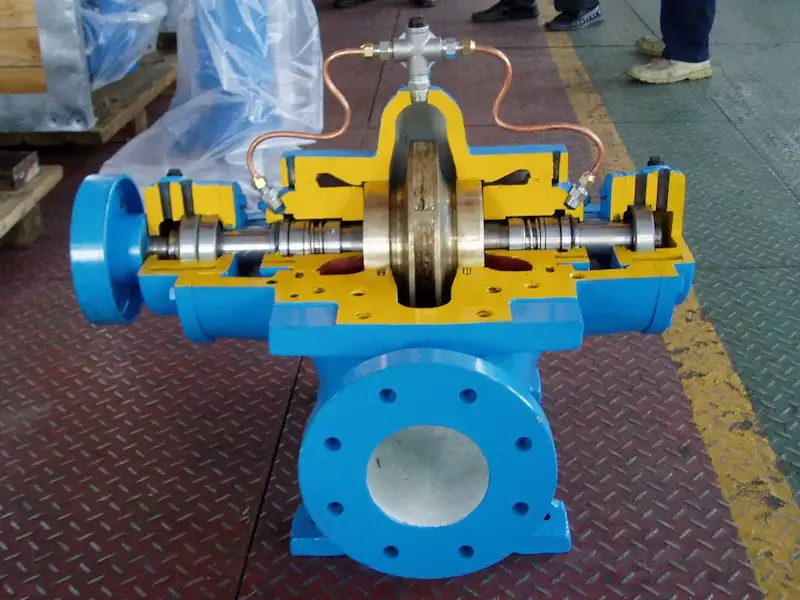

The SA Type Double Suction Split Case Pump delivers exceptional performance for high-capacity water applications where reliability and efficiency are paramount. This horizontal centrifugal pump features a double suction design that allows water to enter both sides of the impeller simultaneously, effectively balancing axial forces and reducing bearing loads for extended service life.

The horizontally split casing provides unmatched maintenance accessibility, enabling complete inspection of internal components without disturbing pump connections or piping. Engineered for clean water services, this robust pump excels in municipal water supply, large-scale irrigation, and industrial cooling systems. With its optimized hydraulic design and precision-balanced impeller, the SA pump offers superior operational efficiency, making it an ideal choice for B2B clients seeking dependable, low-maintenance water transfer solutions.

🌍 Applications

- Municipal Water Systems: Water treatment plants, distribution networks, and booster stations

- Agricultural Irrigation: Large-scale farm irrigation, agricultural water transfer, and crop watering systems

- Industrial Cooling: Power plant cooling circuits, industrial process cooling, and HVAC systems

- Building Services: High-rise water supply, commercial complex circulation, and fire protection systems

- Water Transfer Projects: Reservoir management, river pumping stations, and inter-basin water transfer

⚙️ Technical Data

| Parameter | Specification Range | Parameter | Specification Range |

|---|---|---|---|

| Flow Capacity | 72 – 5,400 m³/h | Speed | 970 – 1,450 rpm |

| Head | 12 – 125 m | Inlet/Outlet Size | 100 – 800 mm |

| Power Range | 22 – 1,250 kW | Efficiency | Up to 92% |

| Liquid Temperature | ≤ 80°C |

💡 Features & Benefits

- Balanced Hydraulic Design: Double suction impeller eliminates axial thrust, reducing bearing load and extending component life

- Easy Maintenance Access: Horizontally split casing allows full inspection and service without piping disconnection

- High Efficiency Operation: Optimized impeller and volute design achieves exceptional energy efficiency, reducing operating costs

- Robust Construction: Heavy-duty cast iron casing with precision-machined components ensures long-term reliability

- Quick Serviceability: Standardized components and accessible design minimize maintenance downtime and repair costs

- Smooth Operation: Precision-balanced rotating assembly ensures low vibration and quiet performance

- Versatile Installation: Flexible configuration options accommodate various system layouts and space constraints

❓ Frequently Asked Questions

Q: What is the primary advantage of the double suction design?

A: The double suction design balances hydraulic forces on the impeller, significantly reducing axial thrust and bearing loads. This results in smoother operation, longer mechanical life, and reduced maintenance compared to single suction pumps.

Q: How does the split case design benefit maintenance operations?

A: The horizontally split casing allows complete access to the impeller, shaft, and bearings by simply removing the upper casing half, eliminating the need to disconnect piping. This reduces maintenance time by up to 60% compared to end-suction designs.

Q: What types of fluids is the SA pump designed to handle?

A: This pump is engineered for clean water applications including potable water, raw water, cooling water, and other non-abrasive liquids with minimal solid content. For specialized applications, material upgrades are available.

Q: What efficiency levels can we expect from these pumps?

A: SA series pumps typically achieve 85-92% efficiency, making them among the most energy-efficient options for high-capacity water transfer. Actual efficiency depends on specific operating conditions and pump size.

Q: Can these pumps be customized for specific project requirements?

A: Yes, we offer customization options including material selections, seal types, bearing arrangements, and mounting configurations to ensure optimal performance for your specific application needs.

Q: What is the expected service life of SA series pumps?

A: With proper installation and maintenance, these pumps typically provide 20+ years of reliable service. The balanced design and robust construction contribute to exceptional longevity in continuous operation applications.