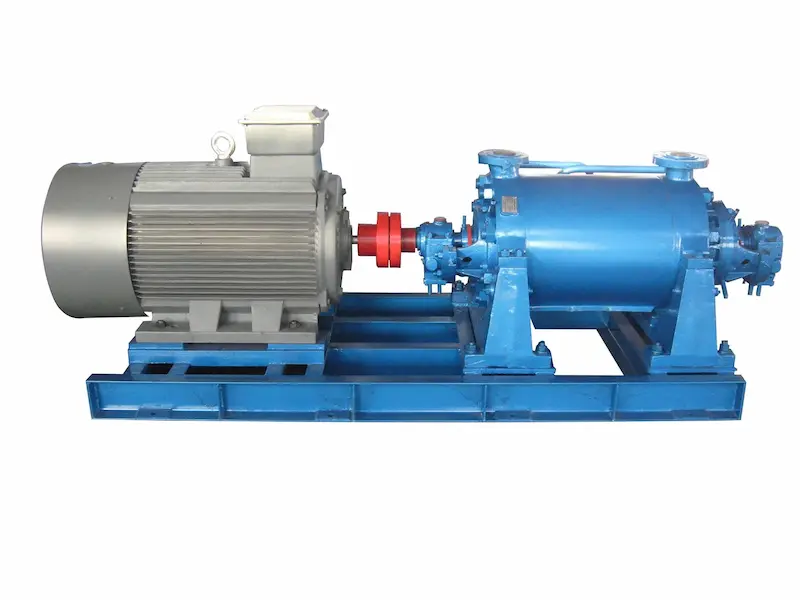

China Boiler Feed Pump Supplier | DG Series High Pressure Multistage Pump for Thermal Power Plant

Product Description

The DG Boiler Feed Pump is a multistage horizontal centrifugal pump designed for high-pressure boiler feed systems in power plants and industrial facilities. With a flow range of 6.3–280 m³/h and head capability up to 1,000 m, it supports a wide spectrum of boiler feed applications. Its robust design handles temperatures up to 170 °C and pressures up to 40 bars, making it reliable in demanding steam cycle systems.

🌍 Applications

- Power Stations / Thermal Plants – supplying high-pressure feedwater for boilers

- Industrial Boilers – chemical, petrochemical, pulp & paper, cement plants

- Combined Heat & Power (CHP) Systems – maintaining circulation in steam networks

- District Heating Systems – when high head and pressure are required

- Large-scale Process Plants – for high-pressure clean water feed to reactors or exchangers

⚙️ Technical Data

| Parameter | Specification | Parameter | Specification |

|---|---|---|---|

| Flow Range | 6.3 – 280 m³/h | Power (Corollary) | 4.0 – 1,250 kW |

| Head Range | 75 – 1,000 m | Inlet / Suction Diameter | 40 – 200 mm |

| Max Temperature | 0 – 170 °C | Operation Pressure | ≤ 40 bars |

| Pump Type | Multistage, horizontal, double-suction impeller | Installation Orientation | Horizontal pipeline pump |

| Package | Export wooden case | Origin / Trademark | China, Suhua |

Product Specifications

| Model | (r/min) | m³/h | L/s | (m) | (%) | (kW) | (m) | |

|---|---|---|---|---|---|---|---|---|

| Shaft power | Motor Power | NPSH | ||||||

| DG 6-25×3 | 2950 | 3.75 | 1.04 | 76.5 | 33 | 2.37 | 5.5 | 2.0 |

| 6.3 | 1.75 | 75 | 45 | 2.86 | 2.0 | |||

| 7.5 | 2.08 | 73.5 | 47 | 3.19 | 2.5 | |||

| DG 6-25×4 | 2950 | 3.75 | 1.04 | 102 | 33 | 3.16 | 7.5 | 2.0 |

| 6.3 | 1.75 | 100 | 45 | 3.81 | 2.0 | |||

| 7.5 | 2.08 | 98 | 47 | 4.26 | 2.5 | |||

| DG 6-25×5 | 2950 | 3.75 | 1.04 | 127.5 | 33 | 3.95 | 7.5 | 2.0 |

| 6.3 | 1.75 | 125 | 45 | 4.77 | 2.0 | |||

| 7.5 | 2.08 | 122.5 | 47 | 5.32 | 2.5 | |||

| DG 6-25×6 | 2950 | 3.75 | 1.04 | 153 | 33 | 4.73 | 11 | 2.0 |

| 6.3 | 1.75 | 150 | 45 | 5.72 | 2.0 | |||

| 7.5 | 2.08 | 147 | 47 | 6.39 | 2.5 | |||

| DG 6-25×7 | 2950 | 3.75 | 1.04 | 178.5 | 33 | 5.52 | 11 | 2.0 |

| 6.3 | 1.75 | 175 | 45 | 6.67 | 2.0 | |||

| 7.5 | 2.08 | 171.5 | 47 | 7.45 | 2.5 | |||

| DG 6-25×8 | 2950 | 3.75 | 1.04 | 204 | 33 | 6.31 | 15 | 2.0 |

| 6.3 | 1.75 | 200 | 45 | 7.63 | 2.0 | |||

| 7.5 | 2.08 | 196 | 47 | 8.58 | 2.5 | |||

| DG 6-25×9 | 2950 | 3.75 | 1.04 | 229.5 | 33 | 7.10 | 15 | 2.0 |

| 6.3 | 1.75 | 225 | 45 | 8.52 | 2.0 | |||

| 7.5 | 2.08 | 220.5 | 47 | 9058 | 2.5 | |||

| DG 6-25×10 | 2950 | 3.75 | 1.04 | 255 | 33 | 7.89 | 18.5 | 2.0 |

| 6.3 | 1.75 | 250 | 45 | 9.53 | 2.0 | |||

| 7.5 | 2.08 | 245 | 47 | 10.63 | 2.5 | |||

| DG 6-25×11 | 2950 | 3.75 | 1.04 | 280.5 | 33 | 8.68 | 18.5 | 2.0 |

| 6.3 | 1.75 | 275 | 45 | 10.5 | 2.0 | |||

| 7.5 | 2.08 | 269.5 | 47 | 11.71 | 2.5 | |||

| DG 6-25×12 | 2950 | 3.75 | 1.04 | 306 | 33 | 9.47 | 18.5 | 2.0 |

| 6.3 | 1.75 | 300 | 45 | 11.44 | 2.0 | |||

| 7.5 | 2.08 | 294 | 47 | 12.78 | 2.5 | |||

| DG 12-25×3 | 2950 | 7.5 | 2.08 | 84.6 | 44 | 3.93 | 7.5 | 2.0 |

| 12.5 | 3.47 | 75 | 54 | 4.73 | 2.0 | |||

| 15.0 | 4.17 | 69 | 53 | 5.37 | 2.5 | |||

| DG 12-25×4 | 2950 | 7.5 | 2.08 | 112.8 | 44 | 5.24 | 11 | 2.0 |

| 12.5 | 3.47 | 100 | 54 | 6.30 | 2.0 | |||

| 15.0 | 4.17 | 92 | 53 | 7.09 | 2.5 | |||

| DG 12-25×5 | 2950 | 7.5 | 2.08 | 141 | 44 | 6.55 | 11 | 2.0 |

| 12.5 | 3.47 | 125 | 54 | 7.88 | 2.0 | |||

| 15.0 | 4.17 | 115 | 53 | 8.86 | 2.5 | |||

| DG 12-25×6 | 2950 | 7.5 | 2.08 | 169.2 | 44 | 7.85 | 15 | 2.0 |

| 12.5 | 3.47 | 150 | 54 | 9.46 | 2.0 | |||

| 15.0 | 4.17 | 138 | 53 | 10.64 | 2.5 | |||

| DG 12-25×10 | 2950 | 7.5 | 2.08 | 282 | 44 | 13.09 | 22 | 2.0 |

| 12.5 | 3.47 | 250 | 54 | 15.76 | 2.0 | |||

| 15.0 | 4.17 | 230 | 53 | 17.73 | 2.5 | |||

| DG 12-25×11 | 2950 | 7.5 | 2.08 | 310.2 | 44 | 14.4 | 22 | 2.0 |

| 12.5 | 3.47 | 275 | 54 | 17.34 | 2.0 | |||

| 15.0 | 4.17 | 253 | 53 | 19.5 | 2.5 | |||

| DG 25-30×7 | 2950 | 15 | 4.17 | 238 | 50 | 19.44 | 30 | 2.2 |

| 25 | 6.94 | 210 | 62 | 23.1 | 2.2 | |||

| 30 | 8.33 | 192.5 | 63 | 24.90 | 2.6 | |||

| DG 25-30×8 | 2950 | 15 | 4.17 | 272 | 50 | 22.22 | 37 | 2.2 |

| 25 | 6.94 | 240 | 62 | 26.4 | 2.2 | |||

| 30 | 8.33 | 220 | 63 | 28.53 | 2.6 | |||

💡 Features & Benefits

- High-Pressure Capability — Able to deliver head values up to 1,000 m, meeting demanding boiler feed requirements.

- Multistage Design — Each stage contributes to pressure, reducing radial load and improving reliability.

- Double-Suction Impeller — Balanced hydraulics lowers axial thrust, improving pump life and stability.

- Wide Operating Range — Effective across large flow and head spans for varied boiler capacities.

- Temperature & Pressure Durability — Suitable for feedwater up to 170 °C and pressures ≤ 40 bars.

- Robust Construction — Designed for heavy-duty industrial environments and continuous operation.

- Low Vibration & Noise — Precision machined parts and balanced design ensure quiet operation.

- Easier Maintenance — Modular design allows staged disassembly, reducing downtime.

- China OEM / Export Ready — Factory direct supply, customizable options, and export packaging.

❓ Frequently Asked Questions

Q1: What is the maximum head this pump can achieve?

A: The DG Boiler Feed Pump is rated up to 1,000 meters head, suitable for high-pressure feedwater systems.

Q2: What kinds of plants typically use this pump?

A: Used in power plants, industrial boiler systems, CHP facilities, district heating, and large process plants where high-pressure feedwater is essential.

Q3: Can it handle high-temperature feedwater?

A: Yes, it supports up to 170 °C, suitable for many boiler cycle conditions.

Q4: How is this pump different from standard multistage pumps?

A: It’s specifically designed for boiler feed service, with double-suction impellers, high-pressure tolerance, and optimized for steam cycle reliability.

Q5: Do you support customized versions?

A: Yes. As a manufacturer, we provide OEM / custom configurations — different stages, materials, connection sizes — to suit your plant’s requirements.

Q6: What is the maximum operating pressure?

A: The pump can operate reliably up to 40 bars of pressure.